As the Southern Hemisphere’s largest manufacturer of high-quality respirators and face masks, Detmold Medical has cemented itself as Australia’s leading manufacturer of high-quality personal protective equipment (PPE).

With a commitment to quality and a strong focus on innovation and sustainability, we continue to pave the way and drive innovation within the medical supplies and PPE industry. However, to understand Detmold Medical’s contributions to the evolving needs of the healthcare industry and PPE in general, it’s important to understand how Detmold first came to be.

Detmold Medical’s story

At the start of 2020, Detmold Medical answered a call to arms from the South Australian and Federal Government in response to the growing face mask shortage due to the COVID-19 pandemic.

In just 18 weeks, we were able to import our own specialist mask manufacturing machines and secure vital raw materials from an Australian family-owned supplier. This allowed us to pivot from global packaging manufacturing specialists to face mask manufacturers in a few short weeks.

As part of the process, we collaborated with industry experts and the local government to set up Australia’s first TGA-certified mask manufacturing facility with onsite face mask testing.

Through a series of collaborations and bold decisions, we were able to achieve an 18-month project in just 18 weeks. An achievement that we’re incredibly proud of to this day. But it’s these key values that continue to drive us to this day, allowing us to pave the way for PPE in 2025 and beyond.

Here are just some of the ways we’re contributing to the evolving needs of the healthcare industry.

In-house testing capabilities

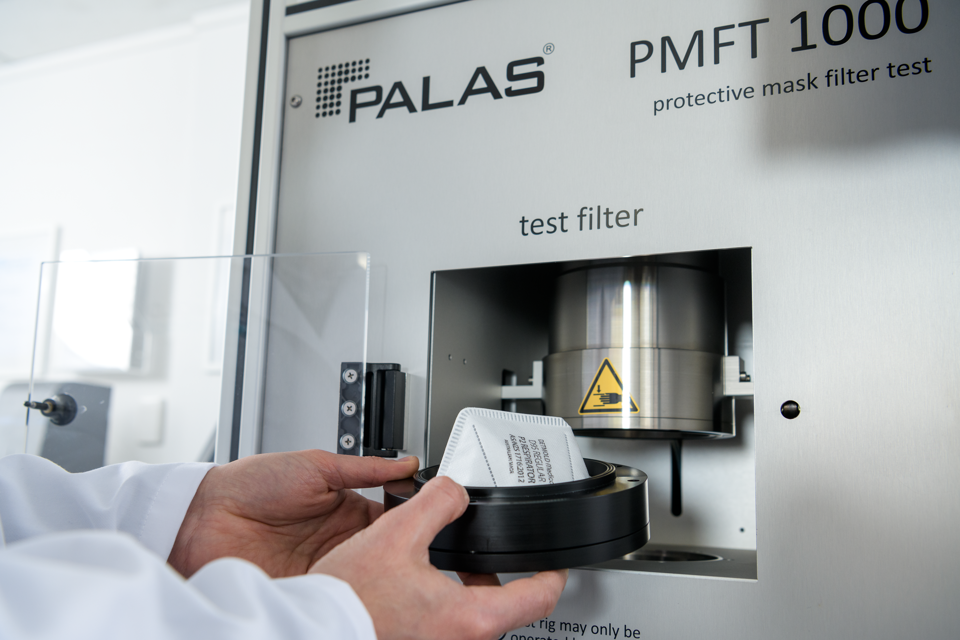

Since 2020, we’ve developed our very own in-house laboratory and testing facility that allows us to validate the performance of our face masks and respirators against AS4381 / AS1716 requirements and international standards. Previously, face masks and respirators were sent overseas for testing and validation. With sovereign PPE testing capabilities, enabling constant monitoring of product performance and quality,

we’re able to quickly identify and resolve any issues at our manufacturing facilities nearby. On-site testing also means we’re able to fast-track approvals for new materials and designs, allowing us to respond to changing market conditions and drive innovation.

Through our world-class testing facility, we’re able to conduct a range of performance tests on-site, this was further enhanced with the installation of the advanced PALAS PMFT 1000 filter tester, which streamlines and accelerates the testing of particulate filtration efficiency and breathing resistance with a high level of precision. This allows us to maintain our commitment to providing high quality, easy to wear PPE products with confidence.

New product development

We pride ourselves on our entrepreneurial spirit and continued dedication to innovation. Having access to an on-site lab allows us to quickly test new materials and designs so we can adapt our product range to the evolving needs of the healthcare industry.

Since our inception in 2020, we’ve collaborated with key customers, frontline workers and industry experts to understand their needs and develop a range of face masks and respirators that are comfortable and provide a high level of protection. Through our industry collaborations, we’ve been able to refine the design of our masks. We’ve also introduced an extended range of sizes of our D95 P2 Respirator Mask to allow for a more comfortable fit.

In addition, we have launched our Tri Panel range expanding our range and we are continuing invest in the development of our portfolio.

Most recently, we introduced our Tri-Panel Respirator Range and our new Level 3 Surgical Visor Mask. This collection includes the L3 N95 Surgical Tri-Panel Respirator, P2 N95 Medical Tri-Panel Respirator and P2 Particulate Tri-Panel Respirator. This collection has been designed specifically for the healthcare and industrial sectors, providing improved comfort and high performance for breathability.

Commitment to sustainability

As part of the Detmold Group, we’re committed to creating sustainable PPE and safeguarding human rights. Our Group operations are guided by the following six positive impact targets developed by the Detmold Group:

● 100% of products with Sustainable Packaging Guidelines applied

● 95% of waste diverted from landfill across all production facilities

● 30% reduction in Scope 1 and 2 emissions per kg of product

● 80% of fibre to be forestry-certified or contain recycled content, with no controversially sourced fibre

● 100% of stock range that meets Towards 2025 Targets

● Three facilities using renewable energy

As a group, we hope to achieve these sustainability objectives by 2025.

Continued community support

Community has always been at the forefront of everything we do at Detmold Medical. From the start, we invested in our local community, hiring over 200 South Australians in 2020, many of whom had lost their jobs due to the pandemic.

During COVID restrictions we donated face masks to several local charities. We provided masks to Adelaide’s Hutt St Centre to protect volunteers as they provided support for the homeless. We also assisted AnglicareSA with a donation of face masks.

At Detmold Medical, we’re committed to driving innovation in PPE, while supporting the environment, our local and national community and the Australian healthcare industry. Explore our range of face masks and respirators to support a family owned, Australian business.